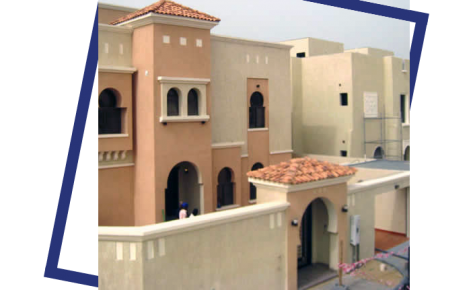

Reinforced Buildings with hollow-core slabs and steel structures with pre-cast cladding which are spread out into three separate areas (and three separate contracts) comprising of 13 total buildings, but treated as if the project is one contract, which are relied upon for the smooth operation of the world’s second largest world-class petrochemical plant, SADARA (Joint Venture between Saudi Aramco and Dow Chemical Company).

Integrating the highest safety and quality standards and practices along with the latest planning and control industry practices for the most efficient and productive construction, this lump-sum turn-key EPC project contains blast proof and other types of building, switchgears, HVAC, fire-fighting, BMS (Building Management System), and much more. The logistics of this project are key to its success, where efficiency and productivity of the many tools, equipment, and workforce required to construct 13 buildings in 3 separate areas is of utmost importance, needless to say the aggressiveness required to manage various loads of dissimilar tasks in-parallel and all in a tight schedule to satisfy the client’s timeline requirements.

The 13 buildings are made up of MCC/PI Buildings, Blast Proof & Normal Types, a Unit Operations Building, an Operator Building, a Loading/Unloading Shacks Building, a Team Building, a Control Building, and an Emergency Generator Building, which serve the following three chemical operations for SADARA:

EO/ESS – Ethylene Oxide and Enveloped Shared System

EOD – Ethylene Oxide Derivate

POD – Propylene Oxide Derivate

- Location: SADARA Petrochemical Plant, 2nd Industrial City, Jubail, KSA

- Started on: July 2013

- Completed on: February 2017

- Client: Tecnicas Reunidas Saudia for Services and Contracting Co. Ltd.